Home › Resources › Case Studies › G100 Export Limitation Project

G100 Export Limitation Project

Hark, partnering with a leading solar installer operating in both the residential and commercial spaces for over a decade, worked with their client to deploy an impressive 1034 kWp SolarEdge fleet.

The SolarEdge Synergy inverter was the perfect choice for this commercial deployment due to its higher yield, enabled by panel-level Maximum Power Point Tracking (MPPT) and up to 175% DC oversizing. Its optimised design simplifies installation and maintenance, ensuring greater system uptime. Additionally, advanced safety features like arc fault detection/interruption and SafeDC™ a SolarEdge feature that shuts down a system to safe DC levels, provide enhanced reliability and peace of mind.

Flexible G100 Export Limitation Solutions.

Large Scale Commercial G100 Projects

Flexible commercial export limitation for G100 compliance.

Like many commercial deployments of this size, the DNO (SSEN – Southern and Scottish Electricity Networks) imposed an export limit of 500kW, to protect energy infrastructure from high levels of export. To abide by this limitation, the client would need a certified G100 export limitation device. This device communicates with on-site energy equipment (inverters, meters, etc.) and curtails excess energy when necessary.

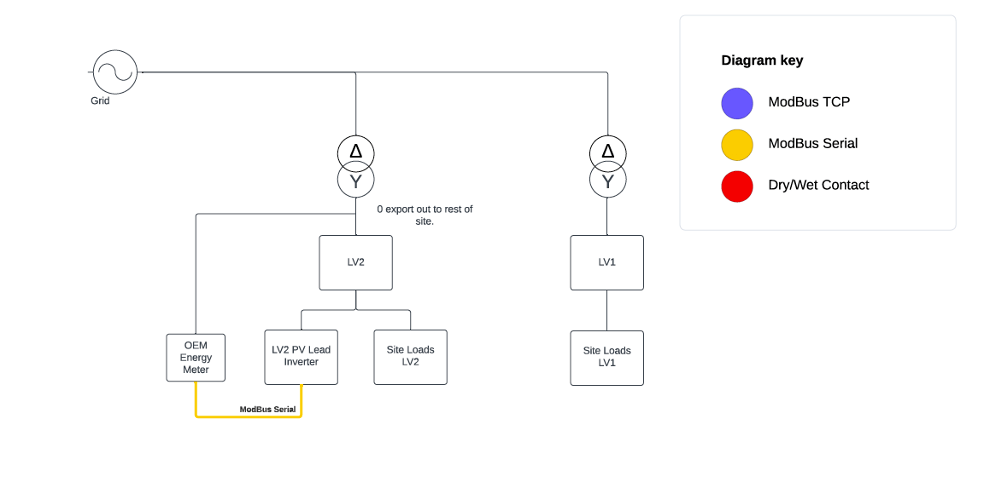

The client’s original site infrastructure didn’t allow for communication between two transformers [pictured below]. The low voltage distribution to half of the site couldn’t export to the rest of the site’s energy infrastructure, leading to efficiency losses. The client wasn’t able to optimise the site and maximise self-consumption. This is why the installer brought in the Hark Distributed Export Limitation Device.

Download This Case Study

Subscribe to our mailing list and receive a PDF case study.

The Hark Distributed Export Limitation Device

ENA-approved G100 Amendment 2.

Hark supply one of only a few type-tested and ENA-approved Export Limitation devices in the UK. With support throughout the entire process, Hark are able to guide installers through G100 projects and the installation of the HDEL.

Rather than needing to deal with any High Voltage (HV) points, the HDEL can summate multiple LV incomers via standard, commercially available metering in order to create a picture of what’s happening across the entire site.

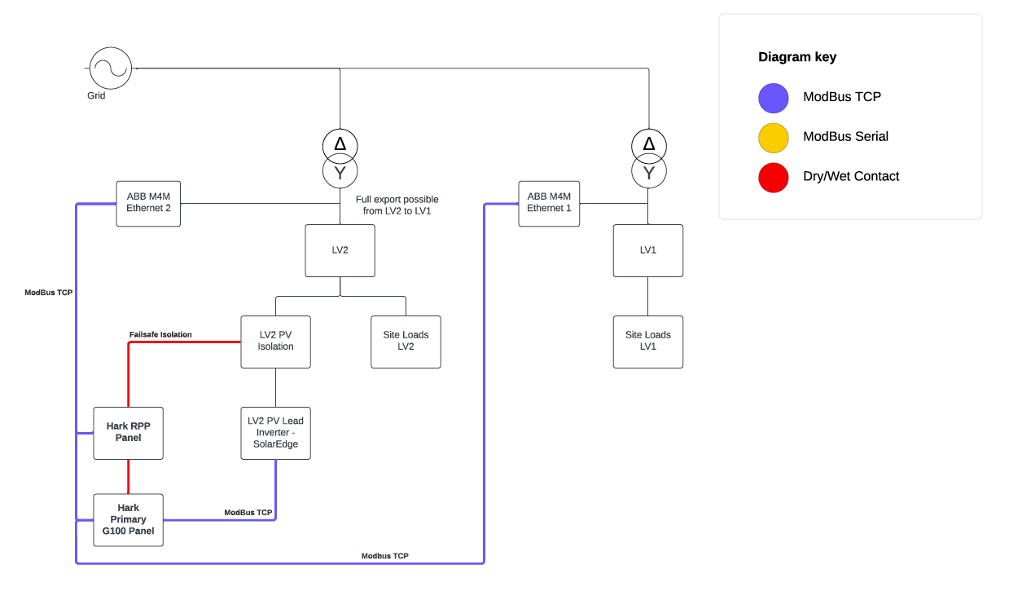

The installer deployed the HDEL hardware, which resulted in an optimised energy system with reverse power protection (RPP) as a failsafe, which is sometimes required by DNOs in high voltage connected sites. The new site infrastructure looked like this:

With the RPP and G100 panels in place, alongside an additional submeter on the second incomer, the hardware is entirely set up. After some simple configuration of Hark’s software, the site can now maximise self-consumption by automatically distributing generated energy across multiple site loads, before ramping down inverter active power to remain under the 500kw export limit.

Hark and the installer formed a combined project team for this deployment, providing a project kick-off, weekly catchups and regular email check-ins, to ensure the smooth delivery of the project. All site visits and support are managed centrally, through the project team.

Project Completion

To become G100 certified the DNO must complete a “Witness Test” of the export limitation device working as intended. Hark engineers are present during the witness test, after which point the site is officially G100 certified. The client can leave the HDEL running in the background, seamlessly and constantly optimising energy production and consumption. This speaks to the “fit and forget” element of the product.

Should any changes need to be made, Hark, the installer or the end customer can remotely configure, modify, and reconfigure the system in the case of staged deployments, or future upgrades and changes to the site.

For installations with SolarEdge inverters, Hark also provides 1 year of free access to the remote monitoring platform, that includes curtailment analysis, and if desired by the installer or client, PV ratio calculations and remote notifications.

Once the handover is completed, Hark can be reached for support at any time, with dedicated support teams on hand to help. This continued relationship can allow for more energy optimisation projects to take place in the future.

Want to Enquire About a G100 Project?

Let’s talk about how the Hark G100 Export Limitation Device could seamlessly integrate into your organisation, just get in touch today.