Hark Connect

Enterprise connectivity for industrial assets, buildings management systems and sensors. Stream data from your assets and machines via industry standard protocols.

Securely connect to and collect data from any system source in real-time using The Hark Platform – an Intel® IoT Market Ready Solution.

Easily connect to your Buildings, Sensors and Industrial Assets

Hark Connect is software that provides connectivity to industrial devices, assets and sensors on the edge, in the cloud and on-premises.

Streamline connectivity, reduce complexity and leverage data for visibility, analytics and optimisation.

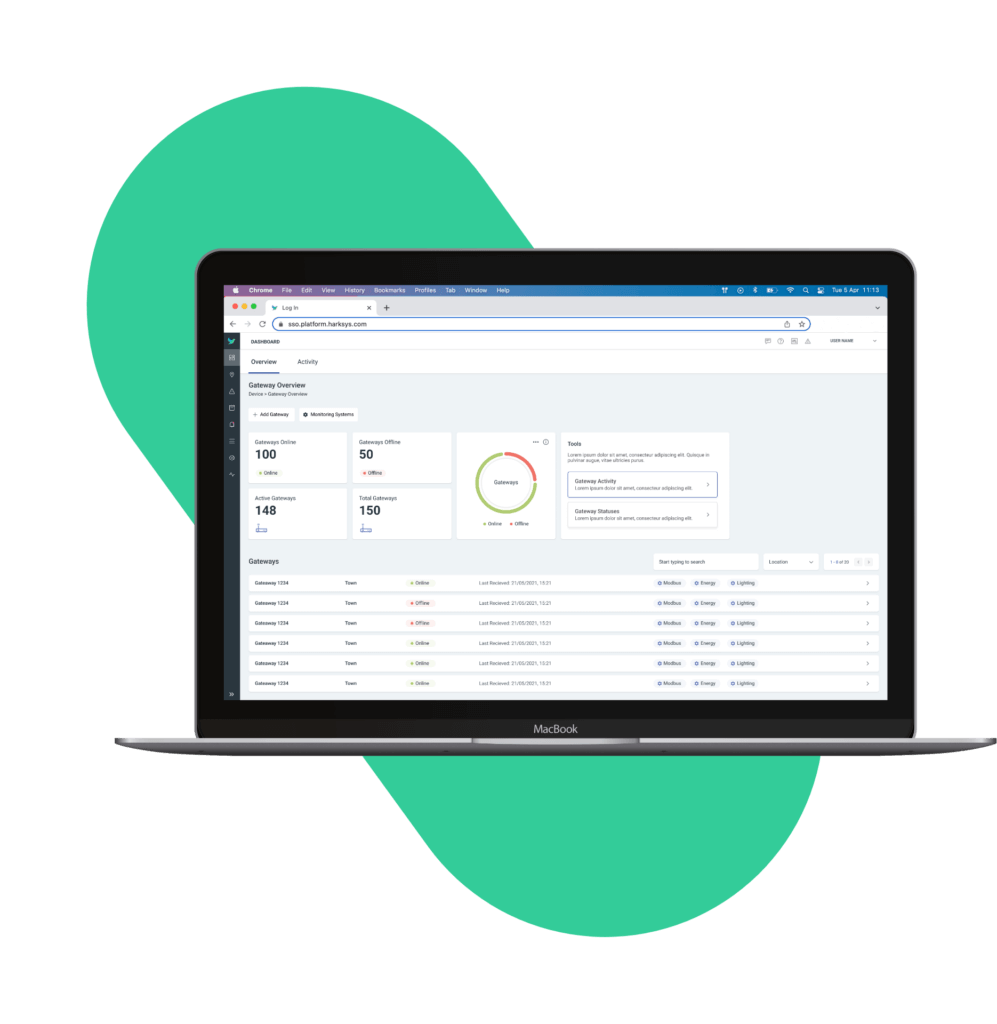

Configuration can be managed by an easy-to-use web interface whether deployed on-premises or in the cloud.

Internal Sensor and Instrument Data

Temperature, power, rpm, flow rate, process values.

External Environment

Data

External weather data, energy prices, other factors.

Process and

Asset Data

Uptime, downtime, utilisation, units / hour, failure rates.

Asset Lifestyle

Data

Maintenance information,

comments and asset history.

Unlock remote data and information to drive down costs and optimise processes

Secure connectivity to existing industrial systems that can unlock data and information, to power cost-effective solutions

Our solutions to ensure multiple vendors of sensors and systems can be integrated into a single Industrial IoT platform for maximum extensibility options, meaning businesses aren’t locked into a single hardware vendor solution.

Compatibility Checker

Do you have a specific device you would like to connect?

Vendor Agnostic Cloud Connectivity

Here are some of the features that help leading organisations connect to and monitor all of the buildings and assets within their estate.

Vendor Agnostic

Develop Custom Integrations

Cloud Connectors

Database, BI Connectors and Backup Options

Edge or Cloud Options

Cloud and Edge Connectivity

Take data straight from your devices to the cloud using Hark Connect on an industrial gateway.

What Can You Achieve With Hark Connect?

Tools to spot anomalies in cost and asset operation, with alerts and notifications to help you prioritise.

Real-time visibility of different assets in a single system, with user-friendly, customisable dashboards.

Download Our Product Datasheet

Everything you need to know about Hark Connect, in a handy 3-page pdf.

Visualise, Analyse and Automate with Hark Analytics

Analyse operational data from industrial assets wherever you are, on a user-friendly, customisable dashboard. You can even set rules and alerts, so the right people are kept up-to-date with the right data, at all times.

Our solutions to ensure multiple vendors of sensors and systems can be integrated into a single Industrial IoT platform for maximum extensibility options, meaning businesses aren’t locked into a single hardware vendor solution.

Connectivity

Secure asset connectivity for retrieving real-time sensor and status information. We use off-the-shelf industrial components, including sensors, gateways and other systems for an extensive range of options. We offer a cost-effective deployment with industry standard protocols and a fully plug-and-play experience for ease and speed.

Visibility

An easy-to-use user interface that allows users to quickly visualise and review asset data in real-time. Graphs, comparisons, status widgets and other components are essentially for easy to access to the data for maximum impact and visibility within an organisation.

Analytics

Business intelligence and analytical tools for teams who are tasked with diving into analytical data at a micro and macroscopic level. Operator; statisticians; data scientists and they are looking for ways to report on or increase visibility of multiple streams of information within a business.

Automation

Quick and easy options for automation such as notifications to applications such as Microsoft Teams, Slack & Zoom. Automation with other systems such as assets and edge devices is also an option. This is ideal to increase efficiency of production systems, assets and various business processes.

What Protocols Can Be Used?

Modbus (TCP/IP) (Serial)

Often used to connect to industrial systems, remote units and SCADA systems. Modbus is a widely used protocol that is supported by many industrial devices such as: PLCs, Sensors, Energy Meters and more.

BACnet (TCP/IP) (Serial)

A communication protocol designed for building and asset automation. BACnet is typically used to connect to, monitor and control building assets. This protocol can be used to monitor and control assets.

OCP-UA (TCP/IP)

A protocol for industrial automation developed for machine to machine communication. It is based on a client – server architecture. Its primary use is for communicating with industrial equipment and systems for data collection and control.

MQTT (TCP/IP)

MQTT is an open standard lightweight, publish-subscribe network protocol that transports messages between devices. The protocol usually runs over TCP/IP; however, any network protocol that provides ordered, lossless, bi-directional connections can support MQTT. Typically it is used for machine-to-machine communication.

HTTP (TCP/IP)

An application-layer protocol for transmitting data across the internet or networks, data such as HTML and web information is transferred over HTTP. It was designed for communication between web browsers and web servers, but it can also be used for other purposes such as machine-to-machine communication.

Which hardware interfaces can be used to connect sensors and systems together?

RS-485

USB

RS-232

Ethernet

A variety of interfaces can be used to connect to sensors and industrial systems. Typically, serial communication is often available on industrial systems, process controllers, energy meters and other types of hardware within industrial settings.

With the advent of the Internet of Things, many manufacturers are enabling connectivity using TCP/IP via Ethernet and Wi-Fi as well as USB serial communication for digital sensors.

Trusted by

We help the world’s leading organisations connect to and monitor their estates, buildings and assets.

Want to Connect Your Assets?

Let’s talk about how IoT could seamlessly integrate into your organisation, just get in touch today.