Home › Solutions › IoT Device and Asset Connectivity › What is BACnet?

Contents

What is BACnet?

BACnet is a communications protocol that is typically used by building management systems or process controllers to connect, monitor and control process values. BACnet can be used to connect to assets and allows multiple devices to initiate conversation and share data and information. BACnet can be used to control HVAC systems, BMS systems and other devices as well as allow them to to connect to graphical interfaces for the end user.

The protocol defines a set of rules and standards, such as the structure of messages or network addressing, and more specifically, it defines what kind of information can be exchanged.

BACnet provides live real time data for all zones connected to the BACnet network. For example, a facility manager can see if the boiler is running, or if an air-conditioner is cooling the building. This gives us incredible visibility into energy monitoring, as we can see exact energy usage in specific assets, which we can use to pinpoint inefficiency.

Before BACnet, every protocol that was used was proprietary, meaning only certain controllers could communicate with each other on a certain platform. This limited the different types of controllers that can be used in a building, enforcing building owners to always use the same controller brand.

ASHRAE developed the BACnet standard to eliminate this, and the standard continues to evolve as new technologies arise. Since then, BACnet has become the most popular type of open protocol (meaning not linked to any specific asset or vendor) used in building automation systems.

How do we use BACnet?

Differing from Modbus, BACnet is a self-describing network. This allows you, as a protocol user, to easily gather information about all of the devices on a BACnet network without prior knowledge.

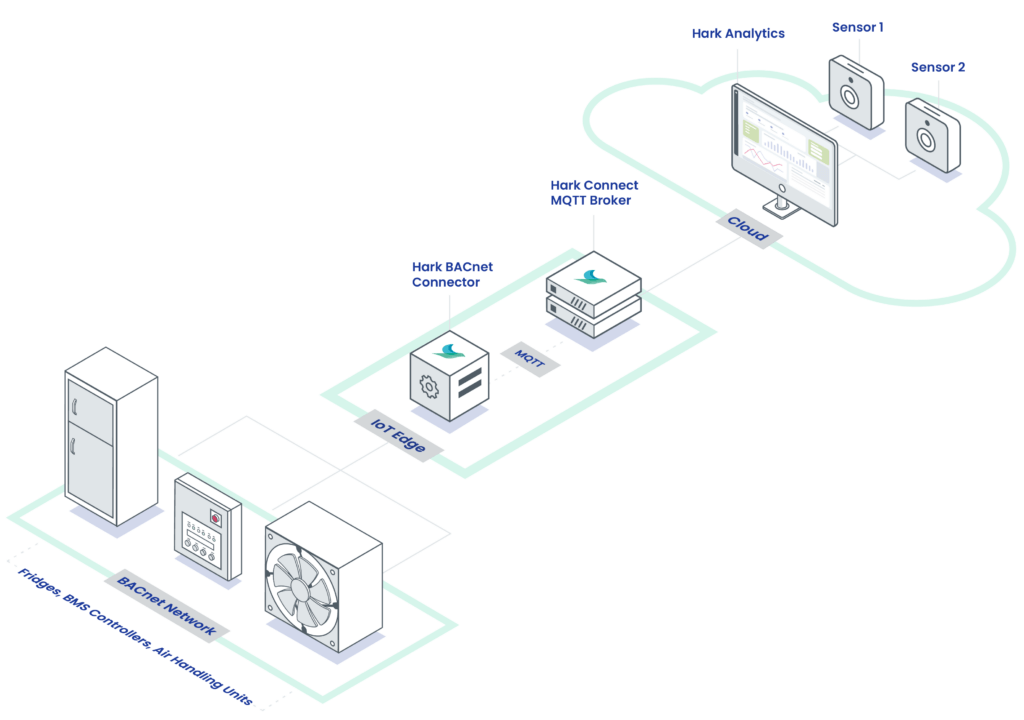

BACnet is an important component for enabling vendor agnostic cloud connectivity for industrial and commercial assets.

The flexibility of BACnet gives us the freedom to implement our solution within an existing set-up, without changing the entire protocol network. The legacy advantage means we can offer a true cost-effective energy monitoring solution, without compromise. We use BACnet to measure HVAC, lighting, and energy monitoring. Even though these systems are not related, they can all communicate on the same network, thanks to BACnet.

Hark has the BACnet to MQTT broker adapter, as well as other communications protocol adapters, which allows standardised MQTT messaging between industrial assets and The Hark Platform.

![]() MSTP (Master Slave Token Passing) is always scanning for new devices that may have been added to the network, which automatically adds them to the graphic interface, meaning the BACnet network can expand as needed.

MSTP (Master Slave Token Passing) is always scanning for new devices that may have been added to the network, which automatically adds them to the graphic interface, meaning the BACnet network can expand as needed.

How to setup BACnet?

Setting up connectivity to systems in order to view trends and alarm notifications can help troubleshoot systems remotely and save on on-site visits as well as analyse energy profiles remotely. There are a few key points that you need to know about BACnet networks and how to set them up correctly. However, when using The Hark Platform gaining connectivity is easily achieved through its intuitive and simple user-interface.

BACnet is typically used to connect assets together, this means that in order to setup BACnet the device you are using must support BACnet, either via TCP/IP or serial communications.

If using a serial network, the typical wiring scheme is to use a three-wire daisy chain connection over MSTP BACnet. This is known as an RS-485 communication.

Each controller needs a unique MAC address, these must be setup in order for the network to run correctly.

The third is the point data information you gather from each controller. When you use a web server, or front-end system, you can collect data to help troubleshoot and monitor the system points like room temperature, airflow, energy usage etc.

Most BACnet networks expose data points in the form of BACnet objects, these are usually setup and configured on the system during commissioning or configuration. These data points could be things such as:

- Temperature values from sensors connected to the controllers or down stream assets

- Set-point values for the control systems which can be remotely set or configured by other assets

- Actuator states and system enums that can describe or indicate the state of a system

Frequently Asked Questions

We work with experts and newcomers to BACnet regularly, here are some of the questions we get most frequently:

Does every asset support BACnet out of the box?

Not always. Many assets in the HVAC (Heating, Ventilation and Air Conditioning ) space do often support these types of protocols, however sometimes they need to be installed via an upgrade. Assets that natively use other communications protocols can still communicate with The Hark Platform.

How do I know if my asset or device supports BACnet?

The first port of call should be to review the OEM manual or any hardware data-sheets for the device and check the sections that refer to communications protocols. If it does support BACnet, it will mention the protocol at least once in the manual.

Another good indicator is to check communications interfaces on the device. A BACNet device will use RS-485 interfaces or TCP/IP (ethernet). This means if there are no connections like this then it is unlikely to support BACnet out of the box.

Is BACnet secure?

Cybersecurity is a continuous effort. BACnet as a protocol was designed prior to the advent of the more thorough security practices in the connectivity space. BACnet doesn’t typically support end-to-end encryption over the wire – this means anyone with access to a BACnet network can listen to device traffic. Authentication and security is not easy to change or implement with BACnet devices and this means great care should be taken when implementing cloud connectivity solutions or similar. Hark Connect is designed to enable secure end-to-end communication between sensors, assets and the cloud.

What is the difference between ModBus and BACnet?

To learn more and understand how our solution can fit into your system. Please get in touch with our team.

If you have any suggestions for improvements please tell us – Contact Us