Home › Solutions › Energy Monitoring › Why Is Energy Monitoring So Important?

Monitor energy & condition of your industrial assets.

Contents

Why is Energy Monitoring Important?

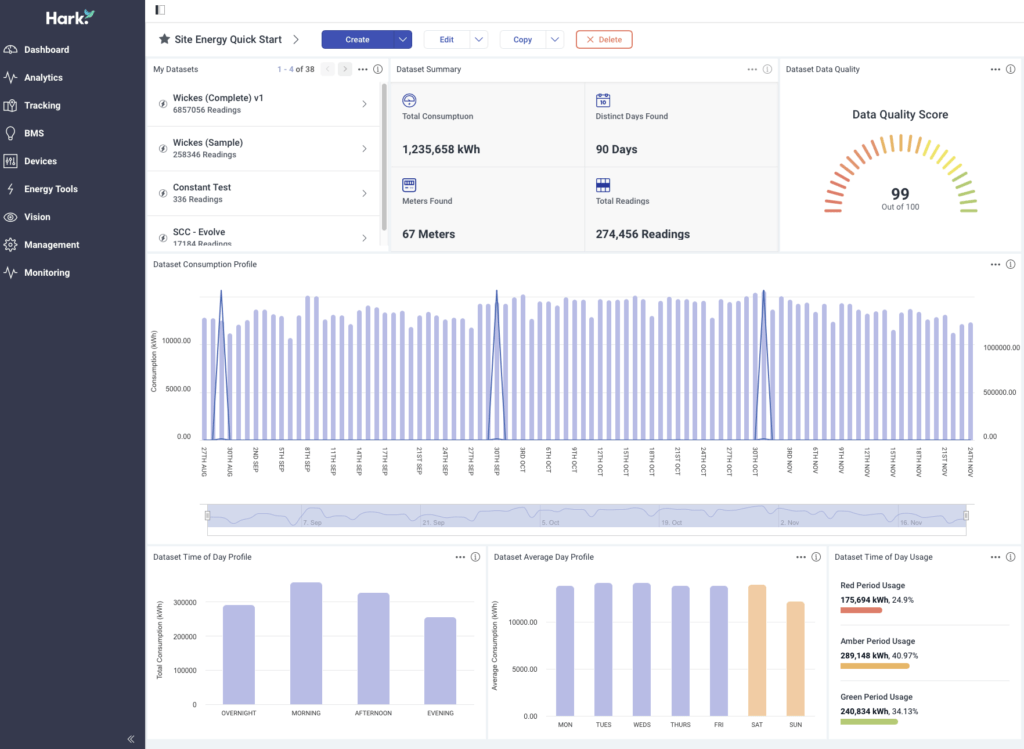

As the name suggests, energy monitoring is the process of monitoring energy consumption, whether that’s an individual asset or an entire building.

Energy monitoring software provides vital insight that can help to control and conserve energy in the future. Without conducting energy monitoring, you won’t be able to distinguish where inefficiencies lie within your business to effectively rectify the situation.

The 2022 energy crisis led the UK government to roll out a ‘support package’ for businesses. This protects businesses in the short term, but in order to address the energy crisis – and climate change as a whole – in the long term, we need to begin understanding our consumption. Energy monitoring is the way to do this.

Here are the core reasons as to why energy monitoring is so vital:

Accurately Measuring

When you look at a utility bill, it provides a final amount of usage and cost, broken down only by electricity or gas. Yet, it cannot directly tell you where the usage came from or the reasoning behind the different costs each month. Subsequently, it doesn’t provide energy managers with the appropriate information they need to make data-driven decisions.

Identify Issues

According to the Carbon Trust, typically 20% of all business’ annual energy costs are wasted through the use of inefficient equipment. Effective energy monitoring on a granular asset level continuously monitors equipment’s performance and energy output and instantly recognises when an asset is not operating efficiently.

Real Time

Energy monitoring becomes even more effective when it is conducted in real-time. As soon as an asset breaks down, instant notifications can be sent to the maintenance team to rectify the situation before excessive amounts of energy is wasted. In addition, the continuous monitoring and analysis of equipment data means predictive maintenance can take place, so assets can continue to operate efficiently at all times with fewer failures. Reducing the cost of factory downtime.

Spikes and Dips

The continuous monitoring of energy consumption provides a daily breakdown of energy usage and makes it easier to identify trends and spikes. By reviewing energy trends over the course of the day, energy managers can determine the best solutions to reduce consumption and possible scheduling options to minimise usage during predicted spikes, such as going off-grid. Real-time energy monitoring is completely scalable, meaning you can monitor one building or an entire estate of facilities.

Cost Per Unit

Monitoring real-time energy data also provides energy managers with better insights into cost per unit of energy. This metric helps organisations to reduce costs in demand or power factor.

If you would like to find out why real-time energy monitoring is vital to your business, then get in touch, we can provide the tools to help you improve efficiency, maximise yield and reduce waste energy consumption.