What is mechanical vibration analysis?

Vibration monitoring and analysis is the process of monitoring how much a machine, component or systems vibrates or moves during normal operation. It can be used to determine the status or condition of a system and therefore its health or standard operating conditions. Vibration monitoring and analysis can be used to provide early indicators of failures in motors, rotary based systems or structures that resonate during normal operation.

How do you measure vibration?

Vibration is typically measured using an accelerometer. An accelerometer generates a voltage signal that corresponds to the amount of vibration and the frequency of vibration that the machine is producing. Different types of sensors are available for monitoring vibration, however, the selection of the most appropriate is application-specific, with the following factors as key considerations:

- Sampling rate required: best practice suggests a sampling rate of 10 times the upper end of the system frequency range.

- Vibration amplitude: ensure the sensor selected is able to measure the full range of amplitude.

- Sensitivity: higher sensitivity accelerometers are required for lower frequency applications

- Number of axes: measurements along one axis is the most common, however triaxial accelerometers can also measure the direction of vibration, such as rotational vibration.

- Weight: sensors should weigh no more than 10% of the test structure.

- Mounting options: contact or non-contact sensors are available.

- Environmental constraints: temperature, humidity, magnetic fields or noise can all have an impact on accuracy of measurements.

- Signal conditioning: required to reduce measurement error. It involves manipulation of the signal, and may include filtering of noise, or signal amplification.

What types of mechanical vibration analysis are there?

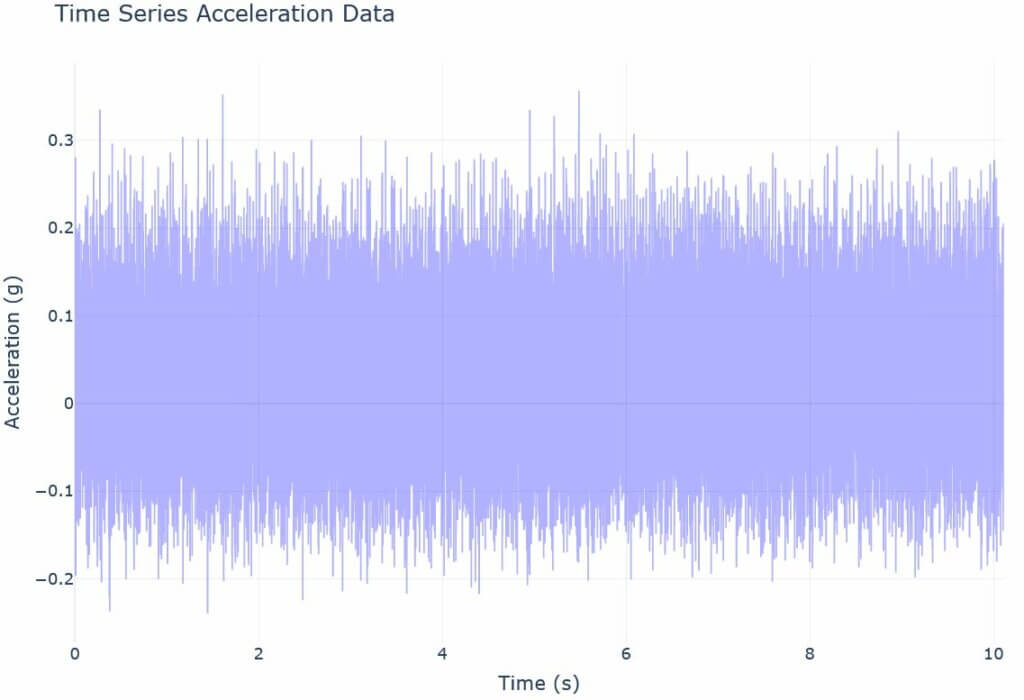

Vibration analysis can be performed on the time waveforms collected from sensors, but analysis is often also required in the frequency domain for further insight.

Time-domain analysis can be useful for looking at the overall performance and condition of a system. For example, we can determine if vibration limits are within certain thresholds required for regulatory purposes.

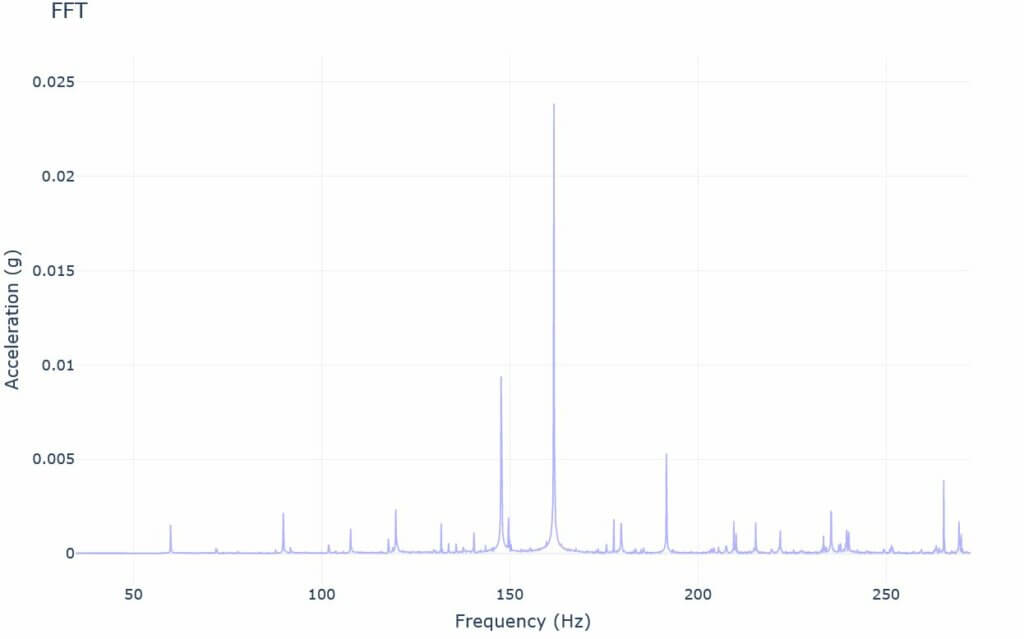

Waveforms however often contain a number of different components, with a mixture of vibrations making up the trace. Time-domain analysis doesn’t allow us to decompose a trace into these individual components, which is where analysis in the frequency domain comes in.

Using algorithms such as Fast Fourier Transforms or Power Spectral Density allows us to decompose waveforms and analyse components within the trace. This allows us to identify sources of abnormality. Analysis in the frequency domain is where we gain the most insight, and is often used to detect equipment faults, misalignment or fatigue.

What are the characteristics of vibration?

Characteristics of a vibration profile we may look at during analysis of a trace may include:

- Peak amplitude

This can be useful for detecting ‘shock’ events (sudden acceleration).

- Crest factor

The ratio of the peak acceleration to the RMS acceleration, so it is unitless. Occasional shock events may have a very high crest factor. Crest factor can be an early indicator of wear.

- Phase

The difference between 2 signals can be compared using units of an angle- known as the phase. This is used alongside FFT to compare signals, and determine factors such as misalignment and unbalance.

- Velocity

Used to determine damage potential and destructive force of vibration. The RMS value of velocity shows the best sign of vibration severity.

- Acceleration

Used for calculation of velocity and displacement and to determine if the structural signature of our system changed by using RMS values.

- Kurtosis

Characterises how ‘peaky’ a signal is, and is often used to predict fatigue of a part.

- Standard deviations

Gives a measure of the amount of variation in a value. We can calculate the standard deviation of characteristics such as acceleration, displacement or velocity.

- Resonance

Occurs when a system is exposed to vibration which matches its natural frequency. However expose to resonance can severely damage assets, and drastically shorten their life span. We can even change a systems resonant frequency by altering the mass or stiffness, or by adding or removing damping.

What are the benefits of monitoring mechanical vibration?

By tracking assets over time, we can determine what is normal behaviour for a system, and therefore identify when a system isn’t operating as expected. By using analytical methods such as Fast Fourier Transforms or Power Spectral Density – allowing us to get a deeper insight into the vibration trace – we can focus our attention and spend our efforts on a specific area.

We can identify mechanical unbalance, looseness or unexpected vibration levels, as well as obtaining early indications of wear and fatigue of a system. Furthermore, allowing us to avoid certain frequencies, such as resonant frequencies, which could have catastrophic damage to our systems.

For more information on how you can monitor your industrial assets and maximise efficiency, contact hello@harksys.com.