What are shifts?

In an industrial setting, operations often work on predefined schedules known as a shift. These shifts include operation/production time, maintenance time and break times. Planning shifts can be challenging, as unforeseen circumstances or unplanned maintenance can result in changes to shift duration or machine operation.

Similarly, changes to shifts can have a knock-on effect to other areas of the business and workflow, leading to project delays or reduced efficiency.

Why is shift control and analysis important?

By adopting IoT solutions (wireless networking of assets through the use of sensors along with data analytic platforms), equipment and processes can be controlled and managed using real time data. Shift patterns can be identified, with any changes from an expected norm detected. This can lead to early discovery of equipment failures or insufficient planning and connectivity with other assets.

The more we learn about shifts and the factors which influence performance, efficiency and downtime, the more data we have to make informed decisions around shift planning. Shift planning can account for around 20% of an operation managers schedule [1]. Not only does shift planning have an impact on productivity, it also has a massive impact on energy consumption and therefore cost.

What insights can we obtain from shift analysis?

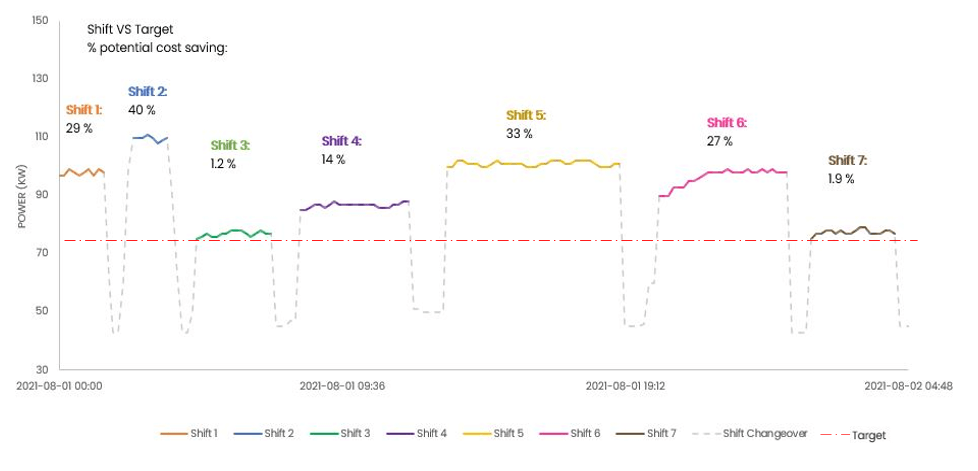

Detecting individual shifts allows for shift reporting; providing stats on each shift such as energy consumption, productivity, downtime or defect rate. This can provide an instant snapshot of a assets performance, or give an indication of variation of performance over time, or even in comparison with other assets.

By analysing individual shifts, we can identify the ‘best’ shift in terms of energy consumption and productivity, and use this as a target for future shifts. Any deviations from this target can be flagged, allowing for investigation into poor performance. Similarly, as shift planning and connectivity between assets improves, the asset can be re-baselined and the target lowered. The goal here is a continuous increase in knowledge and continuous improvements in efficiency targets.

Worker shifts

Likewise, IoT solutions make it possible to analyse both machining shifts and worker shifts. By using sensor systems to align workers with activities, worker performance can also be measured allowing for optimum coordination of worker and machine shift.

Asset Control for a Reduction in Consumption

A clear asset control strategy can not only provide more clarity around operation and asset performance, but also eliminate extended break times or shift changeover.

For manual asset shift changeover, production, and therefore energy performance, can be highly dependent upon training of the operator. Providing sufficient training is essential to ensure manual operation runs according to a shift schedule. However by automating shift changeover processes, this level of human error can be eradicated. Similarly, by adopting IoT software to allow for automated reporting and analysis of shifts can aid in streamlining the process.

Interconnected systems and good quality data allows for shift analysis and reporting, with the potential to improve downtime, reduce energy losses in shift changeover, or identify any abnormalities in an asset’s performance. All of which can lead to an increase in profits and productivity.

To hear more about how asset connectivity and data analytics can help you, contact the Hark team today.

References

[1]- https://throughput.world