However, we’ll never consider ‘Power Factor’. Larger companies, with a physical infrastructure, are always looking to reduce their energy costs. In an effort to reduce waste energy and drive down energy costs, companies will attempt to make their use of energy more efficient by improving the Power Factor of said infrastructure.

What is Power Factor?

Getting technical, first we must define the following terms:

- Actual Power – Also known as Real, True & Active Power, is the minimum power required to power a device or electrical system, expressed in kW (kilowatt).

- Reactive Power – Also known as Useless Power, expressed in KVAr, is the extra power used by an electrical system that either dissipates or is stored and later returned.

- Apparent Power – The product of Reactive Power & Actual Power. The amount of power that must be provided to an electrical system to fully power it, taking in to account the power that will dissipate.

In technical terms, Power Factor of an AC electrical power system is the ratio of Actual Power to Apparent Power. A lower Power Factor results in more electricity being drawn to supply the Actual Power.

Q = P / SPF = True Power / Apparent Power Power Factor ranges from -1 to 1, 1 being the most efficient; no power is being wasted. In a purely resistive load, the Power Factor is 1. Sadly, due to inductive and capacitive loads a Power Factor of 1 is not achievable.

In an inductive load, this is due to the amps in a power supply causing a lag to the volts. The resulting lag is the Power Factor. In a capacitive load, the Power Factor is the reverse, the volts causing lag to the amps.

Take a nice cold pint. When filling up a pint, we need a total of 500ml of beer (Actual Power, in this analogy). However, we know that we’ll need to provide more beer to the glass, as some of the beer will create the head. In this case, the head of the beer is Reactive Power, and is wasted.

If the head of the beer takes up 10% of the glass, we’d need to supply another 10% of beer after the initial 500ml to get a full pint. Therefore, the power factor is .9.

.9 = 500 / 550PF = TP / AP If an electrical system requires 1kWh to run it for an hour, and the Power Factor is .7, you’ll need to draw 1.3kWh from the grid, to account for the wasted .3kWh. We’re drawing more, just to waste it.

What causes bad Power Factor

As explained above, inductive and capacitive loads cause a lower Power Factor. Inductive loads are caused by devices with moving parts, including fans, vacuum cleaners and the compressors within refrigerators and air conditioners.

Capacitive loads do not exist alone, however capacitors are used in most appliances, including electric motors, power supplies and pretty much all circuitry these days.

Companies with HVAC systems, refrigerators and lighting systems, like food retailers, will see their fair share or inductive and capacitive loads resulting in a large amount of Reactive Power.

As these devices all cause the Power Factor to be lower than 1, that adds up and increases the amount of energy drawn from the source thus resulting in the buyer paying more for energy that they aren’t using efficiently.

Identifying a Bad Power Factor

In order to identify your Power Factor, you’ll want to become familiar with energy monitoring systems, luckily, we have one to hand…

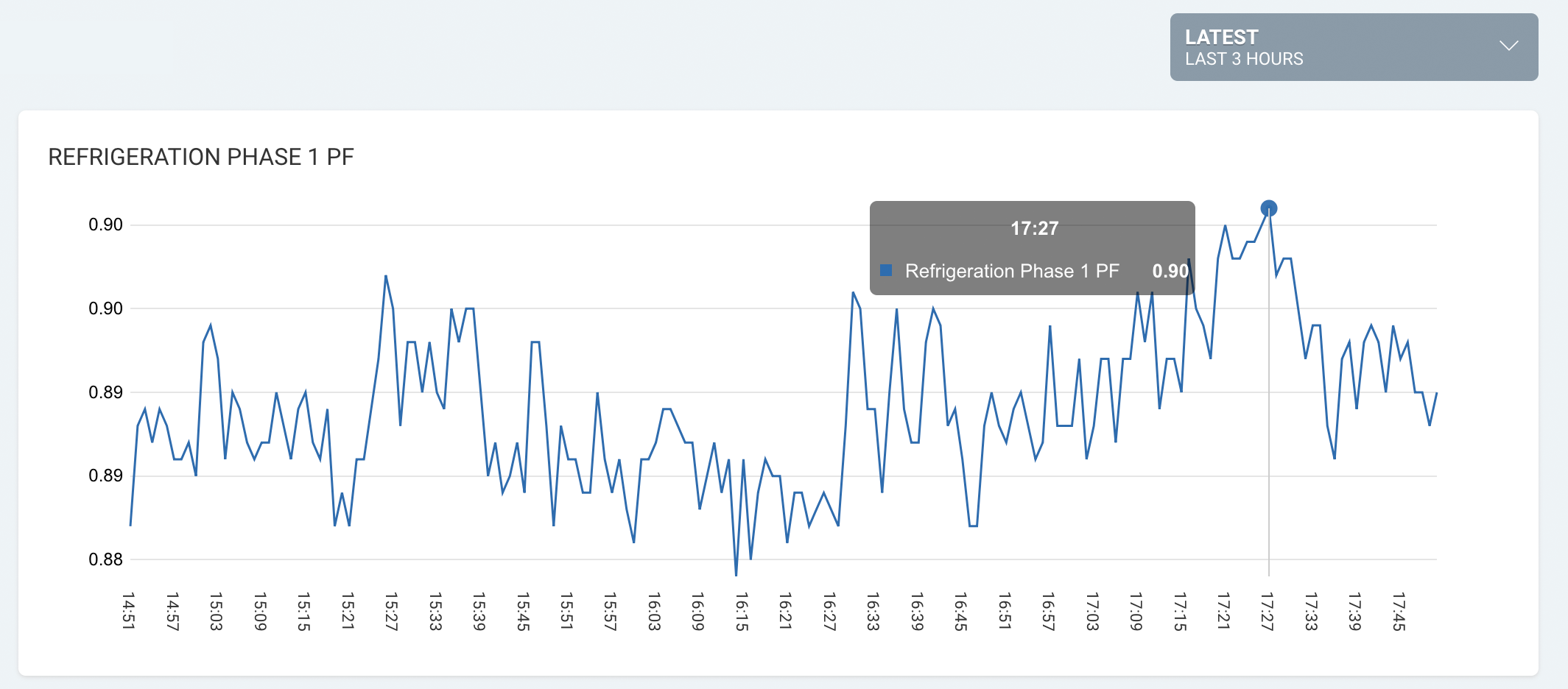

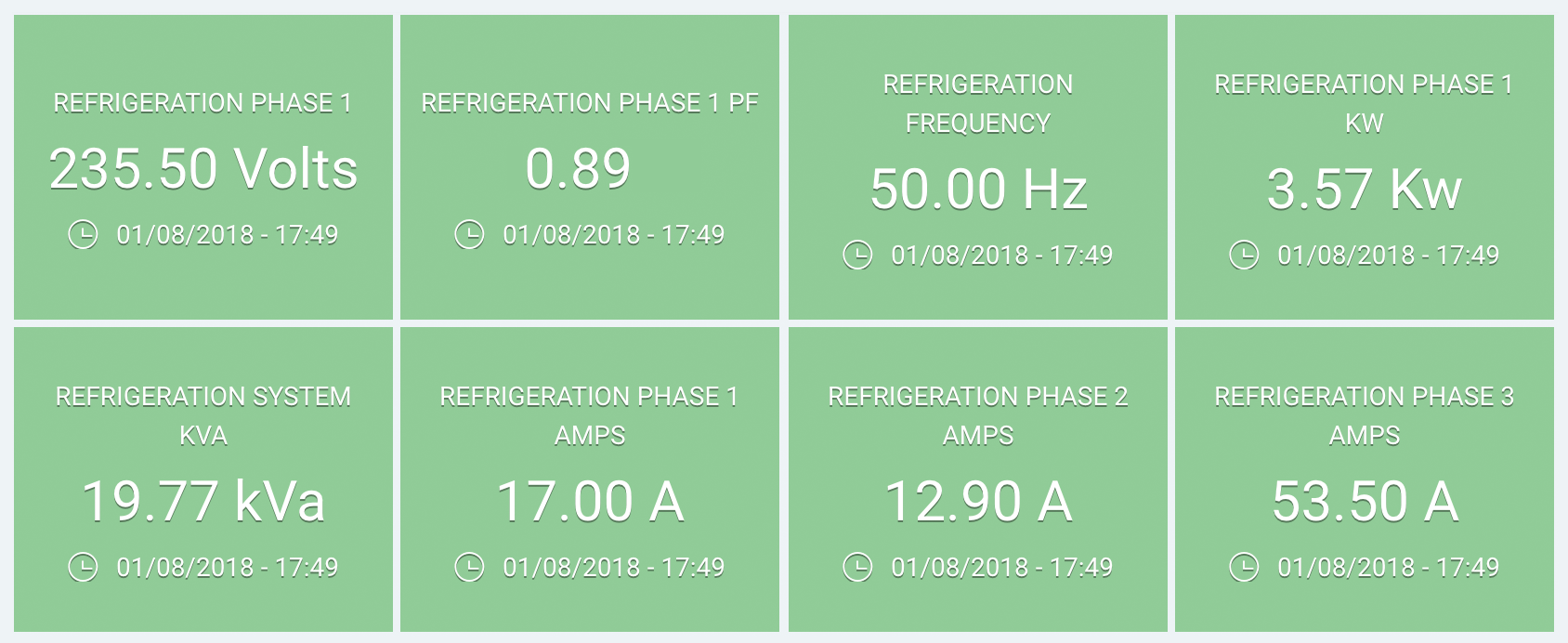

In the picture below, you can see that The Hark Platform is monitoring a refrigeration system with a retailer, in which the Power Factor fluctuates, between .88 and .9.

You’ll also see that we are able to monitor current Kw draw and individual phase frequency, amperage and volts.

Benefits of Power Factor Correction

Power Factor Correction systems can be installed to clean up a systems Power Factor. Most commonly there are 3 types, Capacitor Banks, Synchronous Condensers and Phase Advancers. Some systems are quoted to have a return on investment from just a couple of months and up to 3 years.

Some of the benefits of an improved Power Factor are:

- Significant and immediate savings on cost and energy efficiency

- Longer device lifetime by way of efficiency

- Reduced usage of infrastructure capacity, potential to grow

- Reduction in Low-Power Factor penalties

- Contribution in reduction of carbon footprint

- Increased usable use of the generated renewable energies

To me, the benefits of installing a Power Factor Correction system are massive, and show real improvements that can be made to a business’ bottom line, and contribution to the reduction of energy usage.