One of the most striking things I found during the two-day exhibition was a much more accepted need for energy analytics and industrial IoT. Compared to previous years, attendees of the event seemed much more invested in the idea of IoT deployments, but in many cases didn’t know where to begin or how to select a vendor they could trust.

As you might imagine, this is an opportunity for businesses like us to help educate and demonstrate on the power of connected devices, industrial IoT and energy analytics – which is exactly how we spent our two days at EMEX.

Let’s dive into some of the key topics we discussed…

The increasing need for energy efficiency in large estates

This year big players have had the proverbial ‘Eureka!’ moment with regard to energy consumption and there seems to be a much more unified awareness of the biggest and most important fact when it comes to efficiency: without data we are blind. In the words of Gartner’s Vice President:

“Information is the oil of the 21st century,

Peter sondergaard, vp & global head of research, gartner

and analytics is the combustion engine.”

We had conversations with businesses that have large estates, with an enormous amount of assets; some needlessly turned on ad infinitum. This, we explained, is a common inefficiency – one of many that can be easily overcome through the power of analytics (and automation!)

The difficulty for many however is knowing where to begin; understanding what a deployment should look like, and figuring out all of the complexities and intricacies that come with deploying IoT software into such large enterprises. It was a common theme amongst the crowd we spoke with last week and can be a major roadblock for businesses that are trying to be more efficient.

The answer is professional consultation and expertise. Our recent work with the NHS provides the ability to break down the challenges, benefits, requirements and roadmap for an IoT deployment (at a major scale) by running workshops and discovery sessions. Piece by piece, our consultancy clients are able to visualise their project, before actually deploying anything.

This is the guiding hand that decision-makers often look for during the IoT platform buying cycle.

Communications protocol agnosticism is important to stakeholders

There are some major IoT platform vendors that all share a massive caveat: connectivity restrictions. Whether it’s the vendor of the asset or the communications protocol it uses, IoT software from the likes of Honeywell or Siemens can only provide limited connectivity.

Open communications and the ability to unify ALL data into a singular pane of glass is an extremely important features for an IoT platform that wants to create maximum value for its users.

(FYI: whether your assets use BACnet, ModBus, MQTT or any other open protocol, The Hark Platform can connect to them!)

Automation and control = the proverbial pot of gold

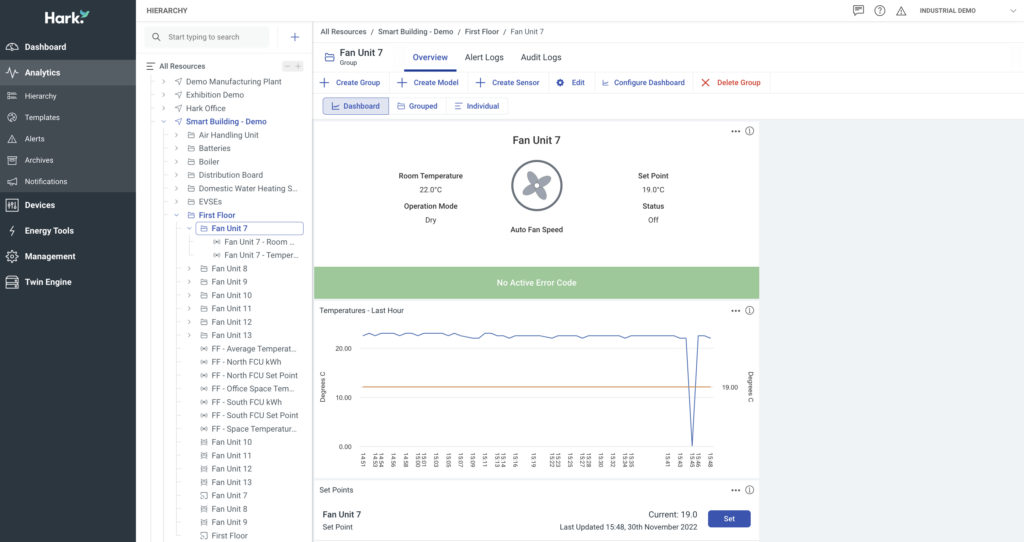

For a lot of the people we spoke to there was an end objective (though, they weren’t necessarily aware that it was the final piece of the puzzle). Automation and control. It’s something we don’t talk about enough really, but also something that sets us apart in the competitive IoT landscape. A young man who approached our stand referred us as an “open loop” version of what they knew to be available – meaning we can pull the data, analyse it and then automatically make the relevant change to the asset.

This is helpful because it lets stakeholders focus attention on other areas while knowing that should any data (energy, temperature, vibration, etc.) thresholds be passed, the correct automation will solve the issue. Any other issues might trigger alerts to be sent to the relevant person (with varying levels of severity, to help with time/job management).

The key message here lies in the cause-and-effect principles that can be introduced to an estate to improve efficiency. However, that juicy ‘pot of gold’ is only found at the end of the proverbial rainbow. Fundamental connectivity and data is needed first in order to power automations and control.

First, we need the data, then we add the automation.

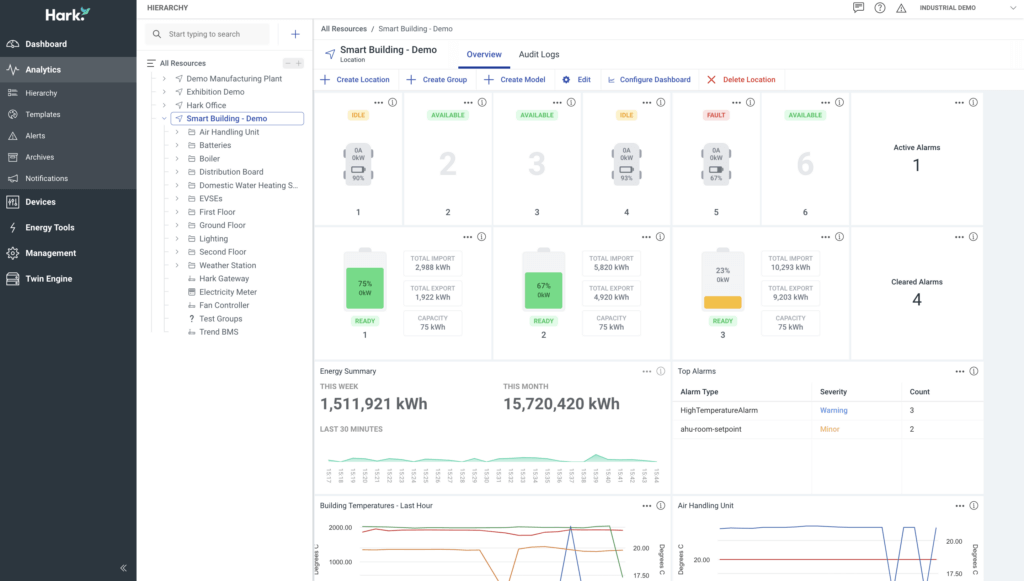

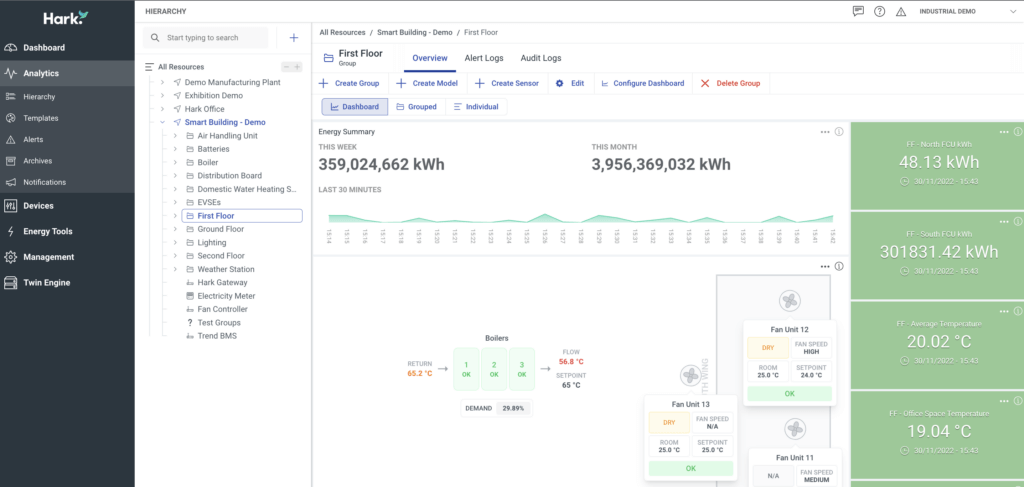

Granular data and energy hierarchies are vital for facilities managers

Here’s a big one, especially for facilities managers: breaking data down on a building-by-building, floor-by-floor, room-by-room or even asset-by-asset level. In order to create maximum impact, you need full visibility into where there are problems or patterns. In some cases, you might need to bill tenants of the same building with separate energy bills. Sub-meter and individual asset insight helps with this.

IoT partnerships and white labelling can open new revenue streams to businesses

There can be times when an IoT platform complements an organisation’s offering to their clients, but they don’t have the resource to create their own. The ability to include the Hark Platform as part of your own product offering is an option with white labelling and our partner program.

As an example, some of the conversations we had with people in the renewable feasibility space began with a voiced concern that they don’t really “deal with” the customer’s journey after the installation of their renewable kit. Ultimately that leaves the journey open-ended and limits customer retention and upsell opportunities.

By introducing The Hark Platform as a new product, this business opens a new revenue stream and carries its customers from feasibility and planning, through to installation and total optimisation.

It’s been a great year of events for Hark, and we’re incredibly grateful for all the connections we’ve made in 2022. Next year we’ll be back to exhibiting at shows and showing the world how to be maximally efficient using energy analytics and industrial IoT.

If you can’t wait until then to catch us for a chat, you can contact us here or stay in touch through Linkedin, Instagram and Twitter. Thanks for reading!